Daftar Isi

- What is Additive Manufacturing?

- The Core Technologies of Additive Manufacturing

- Transformative Benefits of Additive Manufacturing (3D Printing)

- Key Applications Across Industries

- Challenges and Limitations of Additive Manufacturing

- The Future Landscape of Additive Manufacturing (3D printing)

- Conclusion

The evolution of manufacturing processes has been a continuous journey, marked by pivotal shifts that redefine industries and economies. Among these, additive manufacturing (3D printing) stands out as a truly revolutionary force, fundamentally altering how products are designed, produced, and delivered. Far from being a niche technology, it has blossomed into a sophisticated suite of methods that build three-dimensional objects layer by layer from digital models, offering unprecedented flexibility and innovation.

This paradigm shift moves beyond traditional subtractive manufacturing methods, which remove material from a larger block, often generating significant waste. Instead, additive processes optimize material use, enabling the creation of complex geometries and intricate internal structures previously impossible to achieve. From humble beginnings in rapid prototyping, this technology has matured into a robust solution for producing functional components, tools, and even end-use parts across a vast array of sectors.

The widespread adoption of additive manufacturing is driven by its unique capabilities to foster creativity, enable rapid iteration, and facilitate highly customized production. It empowers engineers and designers to break free from conventional manufacturing constraints, opening doors to designs optimized for performance, weight, and efficiency. This freedom accelerates product development cycles and brings novel solutions to market faster than ever before.

As industries grapple with demands for greater personalization, sustainability, and resilience in supply chains, additive manufacturing emerges as a critical enabler. Its disruptive potential lies not just in what it can create, but in how it reconfigures the entire manufacturing ecosystem, promising a future of distributed, demand-driven, and highly adaptive production. This article delves into the core principles, transformative benefits, diverse applications, and persistent challenges shaping this dynamic field.

What is Additive Manufacturing?

At its core, additive manufacturing refers to the process of creating a three-dimensional object by adding successive layers of material. Unlike traditional manufacturing techniques such as machining (subtractive manufacturing) or molding (formative manufacturing), which either remove material or use a mold, additive processes build objects directly from a digital design file, typically a Computer-Aided Design (CAD) model. This layer-by-layer approach allows for the fabrication of highly complex geometries, intricate internal structures, and customized parts with a level of detail and efficiency previously unattainable.

The term “3D printing” is often used interchangeably with additive manufacturing, especially in popular discourse, though additive manufacturing is the broader and more technically precise term encompassing a wide range of technologies and materials. Early forms of 3D printing emerged in the 1980s, primarily for rapid prototyping, allowing engineers to quickly test and iterate designs. Over the decades, advancements in materials science, software, and hardware have expanded its capabilities far beyond prototyping, making it viable for functional parts and even mass production in certain contexts. The fundamental principle remains the same: a digital blueprint is translated into physical reality, one thin layer at a time, resulting in a solidified, multi-dimensional object.

The Core Technologies of Additive Manufacturing

The umbrella term “additive manufacturing” encompasses a variety of distinct processes, each suited to different materials and applications. While they all build objects layer by layer, they differ significantly in their mechanism of material deposition and solidification. Understanding these core technologies is crucial to appreciating the versatility of the field.

Stereolithography (SLA)

SLA was one of the first 3D printing technologies, invented in the 1980s. It uses a UV laser to selectively cure (solidify) layers of photopolymer resin in a vat. The platform lowers after each layer, and the process repeats until the object is complete. SLA is known for producing parts with exceptionally smooth surfaces and fine details, making it ideal for prototypes, master patterns for molding, and intricate models.

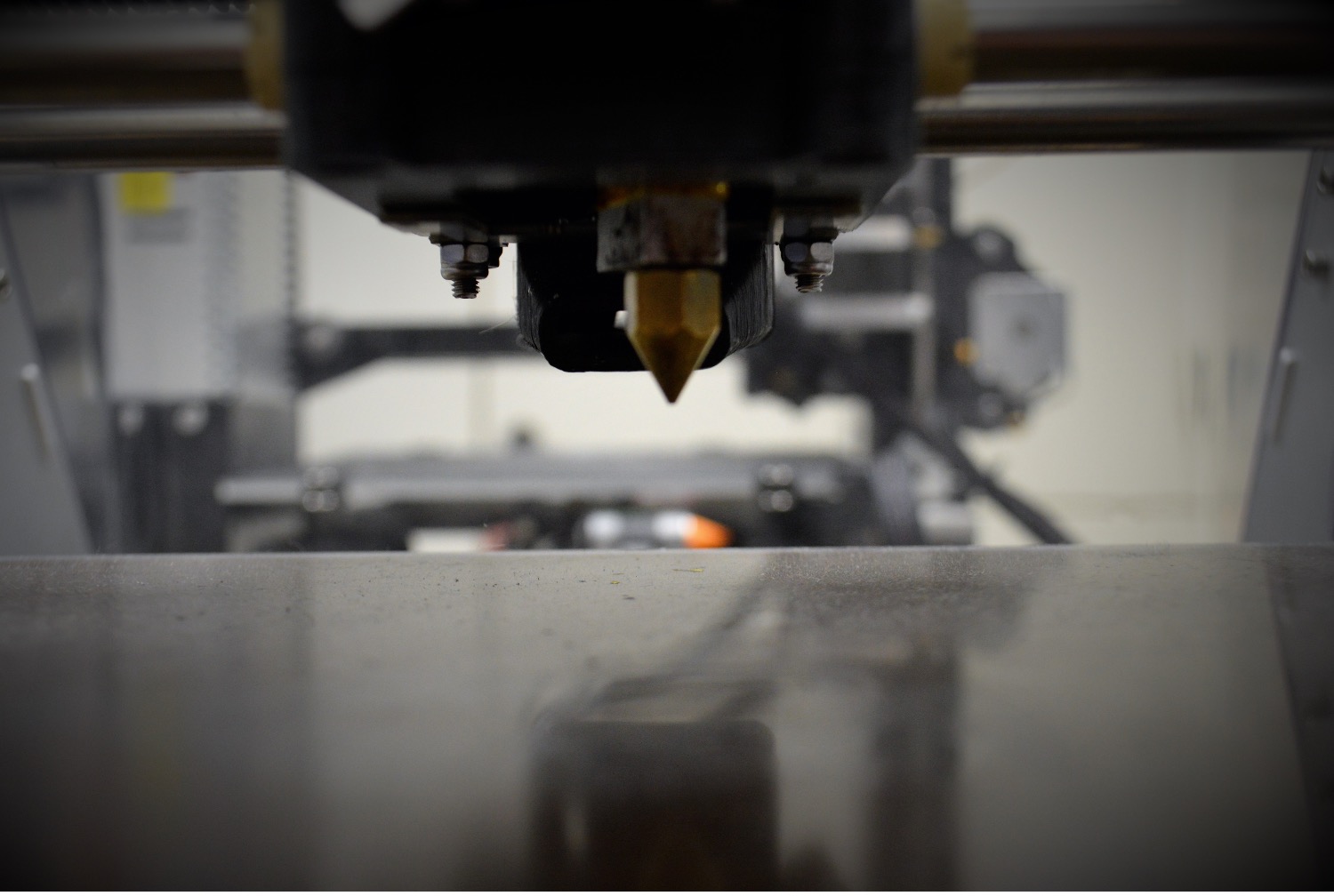

Fused Deposition Modeling (FDM)

FDM, also known as Fused Filament Fabrication (FFF), is perhaps the most common and recognizable 3D printing technology, particularly popular in consumer and prosumer markets. It works by heating and extruding a thermoplastic filament through a nozzle, depositing the molten material layer by layer onto a build platform. FDM is valued for its affordability, ease of use, and ability to use a wide range of engineering-grade thermoplastics, making it suitable for functional prototypes, jigs, fixtures, and some end-use parts.

Selective Laser Sintering (SLS)

SLS uses a high-powered laser to selectively fuse (sinter) small particles of polymer powder, layer by layer, in a heated build chamber. The unfused powder acts as a natural support for the part, allowing for complex geometries without the need for additional support structures. SLS parts are known for their excellent mechanical properties and high strength, making the technology popular for producing functional prototypes and strong end-use components, often in industries like aerospace and medical.

Material Jetting (MJ)

Material jetting processes, such as PolyJet and MultiJet Printing, operate similarly to inkjet printers. They deposit droplets of photopolymer or wax-like materials onto a build tray, which are then immediately cured by a UV light source. This allows for the simultaneous printing of multiple materials with different properties, including rigid, flexible, and transparent materials, as well as the creation of color parts. MJ is excellent for highly detailed, multi-material prototypes, medical models, and visual aids.

Binder Jetting (BJ)

Binder jetting involves depositing a liquid binding agent onto layers of powdered material (which can be metal, sand, or ceramics). After each layer is bonded, the platform lowers, and a new layer of powder is spread. Once printing is complete, the “green” part often requires post-processing steps like curing or sintering in a furnace to achieve full density and strength. This method is particularly effective for producing metal parts and large sand molds for traditional casting.

Directed Energy Deposition (DED)

DED processes typically use a focused energy source, such as a laser or electron beam, to melt material as it is deposited through a nozzle onto a substrate. The material can be in wire or powder form. DED is often used for repairing high-value metal components, adding features to existing parts, or creating large-scale metallic structures. It’s common in industries like aerospace and defense for its ability to work with high-performance metals.

Sheet Lamination (LOM)

Sheet lamination, or Laminated Object Manufacturing (LOM), builds objects by bonding thin layers of material (paper, plastic, or metal foil) together with adhesive and then cutting out the desired shape using a laser or blade. This process is less common for functional parts but can be used for conceptual models or pattern making.

These diverse technologies demonstrate the breadth of additive manufacturing (3D printing), each offering unique advantages in terms of material compatibility, part properties, speed, and cost, allowing for a tailored approach to various manufacturing challenges.

Transformative Benefits of Additive Manufacturing (3D Printing)

The capabilities of additive manufacturing extend far beyond simply creating objects; they offer a suite of benefits that are profoundly impacting industries and design philosophies worldwide. These advantages are driving innovation and efficiency in ways traditional manufacturing methods cannot.

Design Freedom and Complexity

One of the most significant advantages is the unprecedented design freedom. Additive manufacturing allows for the creation of highly complex geometries, intricate internal lattices, and organic shapes that would be impossible or prohibitively expensive to produce with conventional methods. This capability enables designers to optimize parts for performance, weight reduction, and functionality, leading to more efficient and effective products. Topology optimization and generative design become truly viable, producing parts that are strong yet remarkably light.

Customization and Personalization

Customization is another core strength. Since each part is built individually from a digital file, it’s feasible to produce unique, one-off items without incurring significant tooling costs or setup times. This is revolutionary for fields like healthcare, where patient-specific implants, prosthetics, and surgical guides can be rapidly manufactured, precisely tailored to individual anatomical needs. Consumer goods also benefit from mass customization, allowing for personalized products at scale.

Waste Reduction and Sustainability

Additive manufacturing is inherently more sustainable than many traditional methods. By building objects layer by layer, it significantly reduces material waste compared to subtractive processes that cut away from a larger block. Furthermore, the ability to produce parts on demand and closer to the point of use can reduce transportation emissions and inventory holding costs, contributing to a more environmentally friendly manufacturing footprint.

Speed and Agility in Prototyping and Production

The ability to quickly move from a digital design to a physical prototype or even a final part drastically increases speed and agility. This accelerates product development cycles, allowing companies to rapidly iterate on designs, test concepts, and bring new products to market much faster. For small batch production or urgent repair parts, additive manufacturing can bypass lengthy lead times associated with traditional tooling.

On-Demand Manufacturing and Supply Chain Resilience

On-demand manufacturing is a game-changer for supply chains. Instead of maintaining large inventories, companies can print parts only when they are needed, reducing warehousing costs and mitigating risks associated with supply chain disruptions. This distributed manufacturing model can also increase supply chain resilience, as production can be shifted closer to the consumer or a point of need, reducing reliance on single-source suppliers or distant factories.

Cost-Effectiveness for Low-Volume Production

While often perceived as expensive for mass production, additive manufacturing can be highly cost-effective for low-volume production and specialized parts. It eliminates the need for expensive molds, dies, or tooling, which are major cost drivers in traditional manufacturing for small runs. This makes it viable for niche markets, specialized equipment, and custom tooling without the prohibitive upfront investment.

These compelling benefits underscore why additive manufacturing (3D printing) is not just an incremental improvement but a fundamental shift in the capabilities and economics of production across various industries.

Key Applications Across Industries

The versatility and transformative benefits of additive manufacturing (3D printing) have led to its adoption across a remarkably diverse range of industries, pushing the boundaries of what’s possible and reshaping traditional workflows.

Aerospace and Defense

In aerospace and defense, additive manufacturing is crucial for producing lightweight, complex components that are optimized for performance. Parts like turbine blades, brackets, and ducts are manufactured with intricate internal structures, significantly reducing weight while maintaining or increasing strength, leading to improved fuel efficiency and payload capacity. It’s also vital for rapid prototyping of new aircraft designs and for manufacturing on-demand replacement parts for legacy systems, reducing inventory and lead times.

Automotive Sector

The automotive sector leverages additive manufacturing for rapid prototyping of new vehicle components, allowing engineers to quickly test and iterate designs. Beyond prototyping, it’s increasingly used for custom tooling, jigs, and fixtures on the production line. High-performance and luxury car manufacturers are employing it for lightweight, complex end-use parts such as air ducts, interior components, and even specialized engine parts, offering customization and performance benefits.

Healthcare and Medical Devices

Perhaps one of the most impactful applications is in healthcare and medical devices. Additive manufacturing enables the creation of highly personalized solutions:

* Patient-specific implants and prosthetics: Precisely tailored to individual anatomy for better fit and comfort.

* Surgical guides: Custom guides aid surgeons in complex procedures, improving accuracy and reducing operating time.

* Dental applications: Crowns, bridges, and aligners can be rapidly and accurately produced.

* Bioprinting: A cutting-edge area where living cells are printed to create tissues and organs for research, drug testing, and potentially transplantation.

Consumer Goods

For consumer goods, additive manufacturing facilitates mass customization and rapid product development. Eyewear, footwear (e.g., individualized shoe midsoles), jewelry, and personalized sporting goods are examples where bespoke designs can be economically produced. It also allows companies to respond quickly to market trends and offer unique, limited-edition products.

Construction and Architecture

In construction and architecture, large-scale 3D printing is being explored for building entire structures or components like walls and foundations. This offers potential for faster construction times, reduced labor costs, waste minimization, and the creation of complex architectural forms that would be difficult or impossible with traditional building methods. It also holds promise for rapid deployment of housing in disaster-stricken areas or remote locations.

Education and Research

Education and research benefit immensely from the accessibility of additive manufacturing. Students can rapidly bring their designs to life, fostering hands-on learning in STEM fields. Researchers use it to fabricate custom laboratory equipment, complex models for visualization, and test new materials and structures at an accelerated pace, driving scientific discovery and technological advancement.

These examples illustrate that additive manufacturing (3D printing) is not confined to a single industry but is a cross-cutting technology that acts as an enabler for innovation and efficiency across the global economy.

Challenges and Limitations of Additive Manufacturing

Despite its revolutionary potential, additive manufacturing (3D printing) is not without its challenges and limitations. These factors currently restrict its widespread adoption for all manufacturing needs and represent areas of ongoing research and development.

Material Constraints and Post-Processing

While the range of printable materials has expanded significantly, it is still limited compared to traditional manufacturing. Many materials used in conventional processes are not yet suitable for additive manufacturing, either because they cannot be processed or their properties degrade during printing. Furthermore, many additively manufactured parts require significant post-processing steps, such as curing, heat treatment, surface finishing, or support structure removal. These steps can be time-consuming, labor-intensive, and add to the overall cost and lead time, sometimes negating the speed benefits of the printing itself.

Scalability and Production Speed

For high-volume production, additive manufacturing often struggles with scalability and production speed. While multiple parts can be printed in a single build, the per-part build time can be significantly longer than traditional methods like injection molding or casting, which can produce thousands of parts in minutes. This makes it less competitive for mass-market consumer products where volume and speed are paramount. Research into multi-laser systems and faster deposition rates is ongoing to address this.

Cost of Equipment and Materials

The initial cost of industrial-grade additive manufacturing equipment can be substantial, often running into hundreds of thousands or even millions of dollars for sophisticated systems. This high capital investment can be a barrier for smaller businesses. Additionally, the cost of specialized materials (powders, resins, filaments) for additive processes is often significantly higher than their raw material equivalents used in traditional manufacturing, making it less economical for large-scale material consumption.

Quality Control and Certification

Ensuring consistent quality control and achieving certification for additively manufactured parts, especially in critical applications like aerospace or medical devices, presents a considerable challenge. The layer-by-layer nature of the process can introduce anisotropies (directional properties), internal stresses, and porosity, making it difficult to guarantee uniform mechanical properties throughout a part. Developing robust inspection methods, process controls, and standardized certification pathways is crucial for broader industrial acceptance.

Intellectual Property Concerns

The ease with which digital designs can be shared and replicated raises intellectual property (IP) concerns. Unlike physical tooling, a digital file can be instantly duplicated and transmitted globally, making it difficult to protect original designs from unauthorized reproduction. Companies must navigate new strategies for IP protection in a distributed manufacturing environment.

Addressing these limitations is key to unlocking the full potential of additive manufacturing (3D printing) and expanding its reach into even more mainstream industrial applications. Ongoing innovation in materials science, process optimization, and software solutions is continuously working to mitigate these challenges.

The Future Landscape of Additive Manufacturing (3D printing)

The trajectory of additive manufacturing (3D printing) suggests a future where its impact will only deepen and broaden, moving beyond niche applications to become an integral part of the global manufacturing infrastructure. The evolution is driven by continuous innovation in materials, processes, and integration with broader digital technologies.

Advanced Materials and Hybrid Processes

The future will see a significant expansion in the range and performance of printable materials. Expect to see more advanced composites, smart materials (e.g., those that change properties in response to stimuli), bio-compatible materials for medical applications, and high-performance alloys. Hybrid processes, combining additive and subtractive manufacturing within a single machine, will become more common, offering the best of both worlds: the design freedom of additive and the precision finishing of subtractive. This will enable the creation of highly complex parts with superior surface finishes and tight tolerances.

Industry 4.0 Integration

Additive manufacturing is a natural fit for Industry 4.0, the fourth industrial revolution characterized by automation, data exchange, and smart factories. Future additive systems will be highly connected, leveraging artificial intelligence (AI) and machine learning (ML) for predictive maintenance, process optimization, and automated quality control. Real-time monitoring of printing parameters will ensure higher quality and consistency, while integrated digital twins will allow for virtual prototyping and performance simulation, further accelerating design cycles.

Democratization of Technology

As the technology matures, we can expect a continued democratization of additive manufacturing. While industrial systems will remain sophisticated, more accessible and user-friendly systems will emerge, empowering small businesses, educational institutions, and even individual innovators to leverage its capabilities. This will foster a new wave of local manufacturing and entrepreneurship, enabling anyone with an idea and a design to bring products to market.

Mass Customization and Distributed Manufacturing

The inherent ability of additive manufacturing to produce unique, tailored items will drive the trend towards mass customization in more sectors. Consumers will increasingly expect personalized products, from footwear to furniture, manufactured on demand. This will be facilitated by a further shift towards distributed manufacturing, where products are not mass-produced in centralized factories but rather printed closer to the point of consumption, reducing lead times, shipping costs, and environmental impact. This model offers increased supply chain resilience and responsiveness.

The ongoing revolution in additive manufacturing (3D printing) is poised to reshape not just how things are made, but also the very structure of industries, supply chains, and consumer expectations. Its future promises even greater design freedom, material versatility, and a more sustainable, responsive, and personalized approach to production.

Conclusion

The journey of additive manufacturing (3D printing) from a niche prototyping tool to a transformative industrial process marks a significant chapter in the history of production. It has fundamentally challenged traditional manufacturing paradigms, demonstrating that building up, layer by layer, can yield benefits impossible to achieve through conventional methods. This “additive revolution” is characterized by unprecedented design freedom, enabling the creation of intricate geometries and lightweight structures previously confined to imagination.

We’ve explored how diverse technologies like SLA, FDM, and SLS form the backbone of this revolution, each offering unique capabilities for working with a vast array of materials from polymers to metals. The benefits are clear: from rapid prototyping and unparalleled customization to waste reduction and the promise of resilient, localized supply chains. Industries spanning aerospace, healthcare, automotive, and consumer goods are already reaping these rewards, pushing the boundaries of innovation and efficiency.

While challenges remain, including material limitations, production speed for high volumes, cost, and stringent quality control, ongoing research and development are consistently addressing these hurdles. The future of additive manufacturing points towards greater integration with Industry 4.0, a broader range of advanced materials, the rise of hybrid manufacturing processes, and the continued democratization of this powerful technology. Ultimately, additive manufacturing is more than just a set of tools; it represents a paradigm shift towards a more flexible, sustainable, and custom-driven manufacturing landscape, ensuring its role as a key driver of progress for decades to come.

]]>