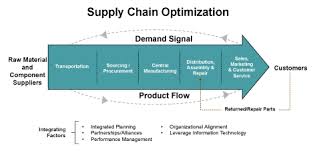

The intricate web of processes, resources, and stakeholders involved in bringing a product from raw material to the consumer’s hands is known as the supply chain. In today’s highly competitive and volatile global market, simply having a supply chain is no longer enough. Businesses must actively pursue supply chain optimization to thrive, ensuring agility, efficiency, and resilience against disruptions.

This critical discipline involves the strategic application of advanced analytics, technology, and robust management practices to enhance every facet of the supply chain. From procurement and manufacturing to logistics and delivery, the goal is to streamline operations, reduce costs, mitigate risks, and ultimately, improve customer satisfaction.

Achieving a truly optimized supply chain means balancing competing priorities. It’s about finding the sweet spot between minimizing inventory holding costs and ensuring product availability, or between reducing transportation expenses and meeting expedited delivery demands. This constant balancing act requires sophisticated planning and real-time adaptability.

The journey towards an optimized supply chain is not a one-time project but a continuous cycle of evaluation, adjustment, and improvement. It necessitates a holistic view, breaking down departmental silos and fostering collaboration across all functions. Companies that master this art gain a significant competitive edge, allowing them to navigate economic shifts, geopolitical events, and consumer trends with greater confidence and profitability.

Understanding Supply Chain Optimization

Defining the Core Concept

Supply chain optimization is the process of maximizing efficiency and effectiveness within a supply chain. It encompasses a holistic approach to improving operations from end-to-end, involving the strategic alignment of all activities from sourcing raw materials to delivering finished products to the customer. The primary objective is to create a supply chain that is not only cost-effective but also agile, resilient, and responsive to market demands and disruptions. This often involves leveraging advanced analytics, digital technologies, and collaborative practices to identify bottlenecks, reduce waste, and enhance decision-making across the entire network.

The Imperative for Optimization

In an increasingly globalized and interconnected economy, businesses face unprecedented challenges, including volatile demand, geopolitical instability, rising costs, and heightened customer expectations. These factors make a passively managed supply chain a significant liability. An unoptimized supply chain can lead to excessive inventory, stockouts, high operating costs, delayed deliveries, and ultimately, dissatisfied customers. Supply chain optimization is no longer a luxury but a strategic imperative. It enables companies to build a robust, agile, and cost-efficient network that can withstand external shocks, capitalize on opportunities, and deliver consistent value to stakeholders. Without it, businesses risk losing market share, eroding profitability, and damaging their reputation.

Key Pillars of Effective Supply Chain Optimization

Achieving a highly optimized supply chain relies on strengthening several interconnected operational areas. Each pillar contributes to the overall efficiency, resilience, and responsiveness of the network.

Demand Planning and Forecasting

Accurate demand forecasting is the bedrock of supply chain optimization. It involves predicting future customer demand for products or services based on historical data, market trends, promotional activities, and external factors. Effective demand planning reduces the risk of overstocking (which ties up capital) and understocking (which leads to lost sales and customer dissatisfaction). Utilizing advanced analytical tools, machine learning, and collaborative forecasting with sales and marketing teams can significantly improve forecast accuracy.

Inventory Management Strategies

Optimized inventory management aims to strike a delicate balance between having enough stock to meet demand and minimizing holding costs. This involves implementing strategies such as Just-In-Time (JIT), ABC analysis, safety stock calculations, and vendor-managed inventory (VMI). The goal is to reduce working capital tied up in inventory, minimize obsolescence, and ensure product availability when and where it’s needed, thereby enhancing the overall flow of the supply chain.

Logistics and Transportation Efficiency

This pillar focuses on the efficient movement of goods from origin to destination. It includes route optimization, mode selection (road, rail, air, sea), carrier management, warehousing, and last-mile delivery. Implementing transportation management systems (TMS) and warehouse management systems (WMS) helps in optimizing routes, consolidating shipments, reducing fuel consumption, and improving delivery times. Efficient logistics directly impacts costs, customer satisfaction, and the environmental footprint.

Supplier Relationship Management (SRM)

Strong relationships with suppliers are crucial for a resilient and optimized supply chain. SRM involves selecting reliable suppliers, negotiating favorable terms, ensuring quality and timely deliveries, and fostering collaborative partnerships. This goes beyond simple transactions to include joint planning, risk sharing, and continuous improvement initiatives. A robust SRM strategy helps in securing critical materials, mitigating supply risks, and fostering innovation, all contributing to overall supply chain optimization.

Leveraging Technology for Supply Chain Optimization

Modern technology is the engine driving the next generation of supply chain capabilities, transforming traditional operations into intelligent, proactive networks.

Artificial Intelligence and Machine Learning

AI and ML algorithms are revolutionizing supply chain optimization by enabling predictive analytics, automated decision-making, and intelligent automation. These technologies can process vast amounts of data to improve demand forecasting accuracy, optimize inventory levels, identify potential disruptions before they occur, and automate complex tasks like order fulfillment and route planning. Predictive maintenance on machinery, anomaly detection in data, and personalized customer experiences are further applications that enhance efficiency and reduce costs.

Internet of Things (IoT) and Real-time Visibility

IoT devices, such as sensors and RFID tags, provide unprecedented real-time visibility into the physical flow of goods. They can monitor asset location, temperature, humidity, and other crucial conditions throughout the supply chain. This real-time data allows for immediate intervention in case of deviations, proactive problem-solving, and enhanced tracking capabilities. From tracking goods in transit to monitoring equipment performance in warehouses, IoT creates a digital twin of the physical supply chain, enabling more informed and agile management.

Blockchain for Transparency and Trust

Blockchain technology offers a decentralized, immutable ledger that can record every transaction and movement within a supply chain. This enhances transparency, traceability, and trust among all participants, from raw material suppliers to final consumers. It helps in verifying product authenticity, tracking origin, managing intellectual property, and streamlining customs processes. For complex global supply chains, blockchain can significantly reduce fraud, improve compliance, and speed up dispute resolution.

Cloud-based ERP and Analytics Platforms

Cloud-based Enterprise Resource Planning (ERP) systems integrate various business functions into a single, cohesive platform, providing a centralized view of operations. When coupled with advanced analytics platforms, they enable real-time data analysis, sophisticated reporting, and scenario planning. Cloud solutions offer scalability, accessibility, and lower infrastructure costs, allowing businesses to adapt quickly to changing demands and make data-driven decisions that are vital for continuous supply chain optimization.

Benefits of Achieving Peak Supply Chain Optimization

The concerted effort towards optimizing a supply chain yields a multitude of benefits that directly impact a company’s bottom line and competitive standing.

Cost Reduction and Increased Profitability

One of the most immediate and tangible benefits of supply chain optimization is significant cost reduction. By streamlining processes, reducing waste, optimizing inventory, and negotiating better terms with suppliers and carriers, companies can drastically lower operational expenses. This leads to improved gross margins and higher overall profitability, allowing for reinvestment or increased shareholder value.

Enhanced Efficiency and Productivity

Optimization efforts invariably lead to improved operational efficiency. Automated processes, better planning, reduced lead times, and elimination of non-value-added activities contribute to higher productivity across all supply chain functions. This means more output with fewer resources, faster cycle times, and a more responsive flow of goods and information.

Improved Resilience and Risk Mitigation

An optimized supply chain is inherently more resilient. By diversifying suppliers, implementing robust contingency plans, leveraging real-time data for early warning signs, and building agile networks, businesses can better withstand disruptions such as natural disasters, geopolitical events, or sudden demand shifts. Risk mitigation strategies are baked into the design, ensuring business continuity.

Superior Customer Satisfaction

Ultimately, supply chain optimization translates into a better experience for the end customer. Faster and more reliable deliveries, fewer stockouts, higher product availability, and improved order accuracy all contribute to increased customer satisfaction. Satisfied customers are more likely to become repeat buyers and brand advocates, fostering long-term loyalty and market share growth.

Sustainable Practices

Modern supply chain optimization increasingly incorporates environmental and social responsibility. By optimizing routes, reducing fuel consumption, minimizing waste, sourcing ethically, and embracing circular economy principles, companies can significantly reduce their environmental footprint and enhance their corporate social responsibility profile. This appeals to environmentally conscious consumers and complies with evolving regulatory landscapes.

Strategies for Implementing and Sustaining Supply Chain Optimization

Embarking on a journey of supply chain optimization requires a strategic, phased approach, recognizing that it is an ongoing process rather than a one-time project.

Holistic Assessment and Goal Setting

The first step is to conduct a thorough audit of the existing supply chain. This involves mapping current processes, identifying bottlenecks, assessing technology infrastructure, and analyzing data flow. Based on this assessment, clear, measurable goals for optimization should be established. These goals could include reducing lead times by a certain percentage, improving forecast accuracy, or cutting transportation costs. A baseline measurement is crucial to track progress effectively.

Data-Driven Decision Making

At the heart of optimization is the ability to make informed decisions based on accurate and timely data. Invest in data collection tools, advanced analytics platforms, and business intelligence (BI) solutions. Develop KPIs (Key Performance Indicators) to monitor performance across all supply chain segments. Encourage a culture where decisions, from inventory levels to sourcing strategies, are backed by data insights rather than intuition alone.

Cross-Functional Collaboration

Supply chains span multiple departments within an organization (e.g., procurement, manufacturing, sales, finance) and external partners (suppliers, logistics providers, customers). Breaking down silos and fostering seamless collaboration is paramount. Implement integrated planning processes, share information transparently, and establish joint objectives that align departmental goals with overall supply chain optimization targets.

Continuous Improvement Mindset

Supply chain optimization is not a destination but a continuous journey. Establish a culture of continuous improvement, often utilizing methodologies like Lean or Six Sigma. Regularly review performance against KPIs, solicit feedback from all stakeholders, and be prepared to adapt strategies in response to market changes, technological advancements, or unforeseen disruptions. Encourage innovation and experimentation to find new ways to enhance efficiency and resilience.

Change Management

Implementing significant changes within a supply chain often requires new processes, technologies, and roles, which can be met with resistance. Develop a robust change management plan that includes clear communication, training, and support for employees. Highlight the benefits of the changes, address concerns proactively, and involve key personnel in the planning and implementation phases to foster buy-in and smoother transitions.

Challenges in Supply Chain Optimization and How to Overcome Them

Despite its benefits, supply chain optimization comes with its own set of complex challenges that organizations must proactively address.

Data Silos and Lack of Integration

A common hurdle is the fragmentation of data across different departments and systems. This creates data silos, making it difficult to get a holistic view of the supply chain and hindering effective decision-making. Overcoming this requires investing in integrated ERP systems, data lakes, and middleware solutions that can connect disparate systems and provide a unified view of information. Establishing common data standards and governance policies is also crucial.

Global Volatility and Disruptions

Geopolitical events, economic downturns, natural disasters, and pandemics can severely disrupt global supply chains. These unpredictable factors make long-term planning challenging. To overcome this, businesses must build resilience through diversified sourcing, developing contingency plans, creating regional supply hubs, and leveraging real-time risk intelligence tools to anticipate and react quickly to disruptions.

Resistance to Change

Implementing new technologies or processes often faces resistance from employees accustomed to traditional methods. Fear of the unknown, lack of training, or concerns about job security can slow down or derail optimization efforts. Effective change management strategies, including clear communication, comprehensive training programs, highlighting employee benefits, and involving staff in the transition, are essential to foster adoption and enthusiasm.

Skills Gap

The advanced technologies and analytical approaches required for modern supply chain optimization demand specialized skills in areas like data science, AI, machine learning, and advanced analytics. Many organizations face a shortage of professionals with these competencies. Addressing this involves investing in upskilling existing staff through training and development programs, strategic recruitment of talent, and potentially partnering with external consultants or technology providers.

Measuring Success: KPIs for Supply Chain Optimization

To truly understand the impact of supply chain optimization efforts, organizations must establish and consistently monitor a set of key performance indicators (KPIs). These metrics provide actionable insights into efficiency, cost-effectiveness, and customer satisfaction.

Order Fulfillment Cycle Time

This KPI measures the total time taken from when a customer places an order to when it is delivered. A shorter cycle time indicates greater efficiency and responsiveness within the supply chain. Continuous reduction in this metric is a strong indicator of successful optimization.

Inventory Turnover

Inventory turnover calculates how many times inventory is sold and replaced over a period. A higher turnover rate generally indicates efficient inventory management, minimizing holding costs and reducing the risk of obsolescence. Low turnover might suggest overstocking or weak sales.

On-Time Delivery Rate

This metric tracks the percentage of orders delivered to customers by the promised date. It is a direct measure of logistics effectiveness and customer satisfaction. A high on-time delivery rate signifies a reliable and well-managed supply chain.

Forecast Accuracy

Forecast accuracy measures how closely actual demand matches the forecasted demand. High accuracy leads to optimized inventory levels, reduced stockouts, and more efficient production planning. Improving this KPI is central to overall supply chain efficiency.

Landed Cost

Landed cost represents the total cost of a product up to the point it reaches the customer, including purchase price, transportation, customs duties, insurance, and handling fees. Reducing landed cost per unit is a direct measure of cost optimization across the supply chain.

Conclusion

Achieving peak supply chain optimization is no longer merely an operational goal; it is a strategic imperative for businesses navigating today’s complex global landscape. From the initial stages of understanding core concepts to the continuous cycle of leveraging cutting-edge technologies and implementing robust strategies, every step contributes to building a more efficient, resilient, and responsive network.

By focusing on key pillars like accurate demand planning, intelligent inventory management, efficient logistics, and strong supplier relationships, companies can unlock significant cost savings, enhance productivity, and bolster their ability to withstand disruptions. Furthermore, embracing advancements in AI, IoT, and blockchain provides the technological backbone necessary for real-time visibility and data-driven decision-making. The ultimate reward is not just increased profitability, but also superior customer satisfaction and the establishment of a sustainable, competitive advantage. The journey towards supply chain optimization is ongoing, demanding continuous assessment, adaptation, and a commitment to innovation, but the benefits undoubtedly outweigh the effort.

]]>